Automatic Maker Machine Kubba Machine

Automatic Kubba Machine video:

Automatic Kubba Machine Description:

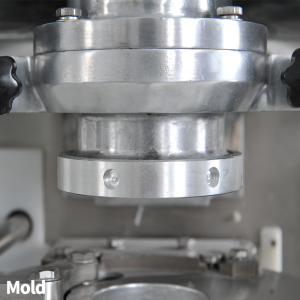

The Automatic Kibbeh Encrusting Machine can change different skin thickness, length, size of food by the machine.It can also change different molds for making different shaped food products.The machine can also make filling soft stuffed pastries such as,…

Specification:

|

Model |

YC-168 |

|

Capacity |

20-150 pcs/min |

|

Specification |

Automatic Encrusting Machine |

|

Product Weight |

10-200g |

|

Power |

Customized |

|

Voltage |

220V/380V |

|

Size |

167*92*129 cm |

|

Weight |

310kg |

Automatic Kubba Machine features:

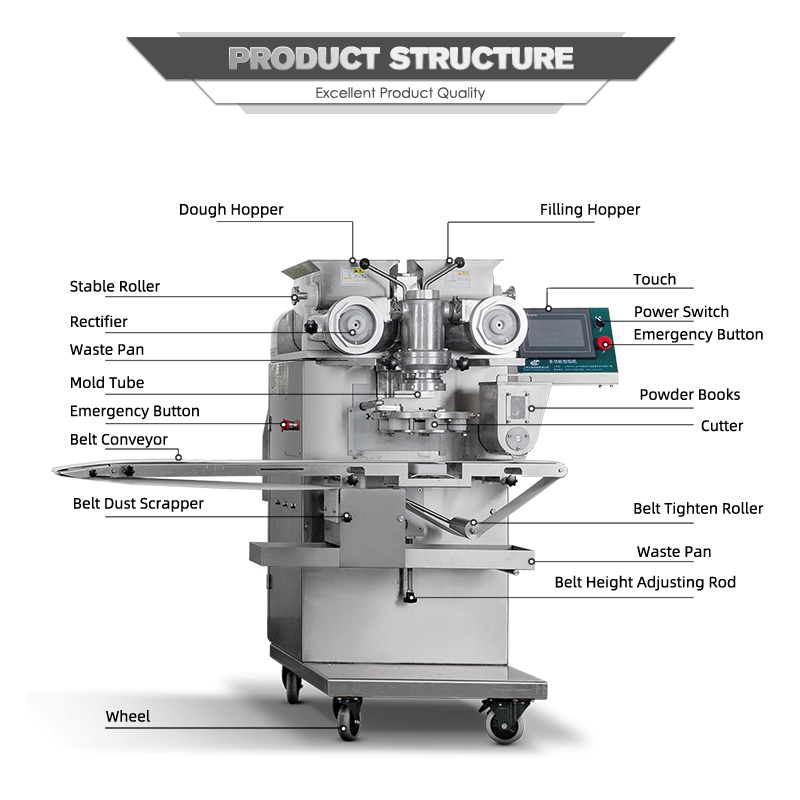

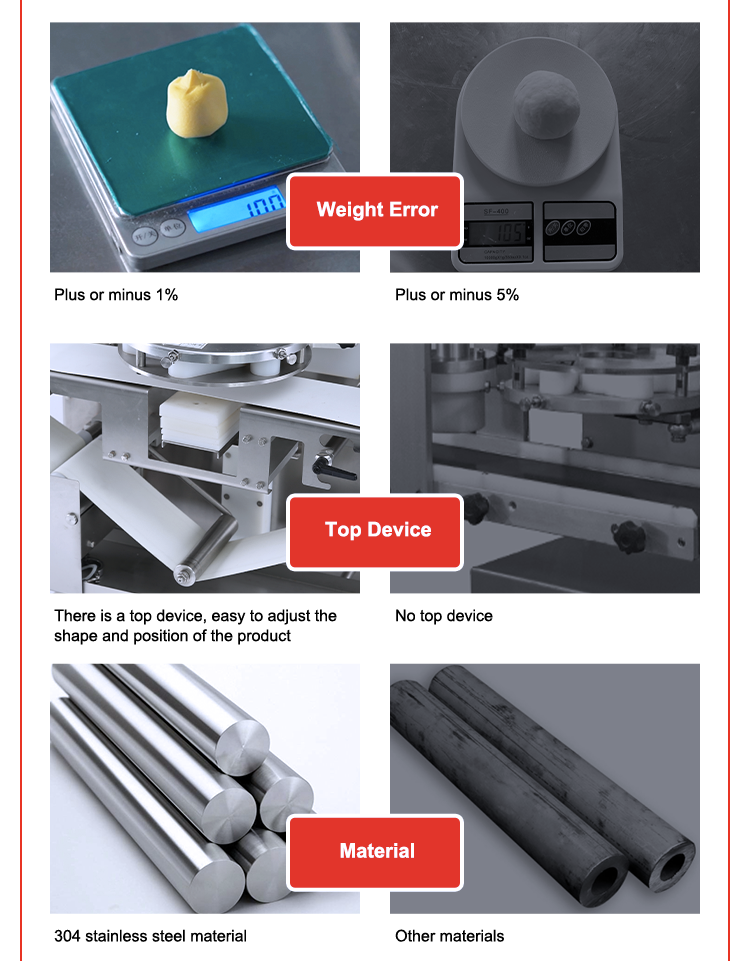

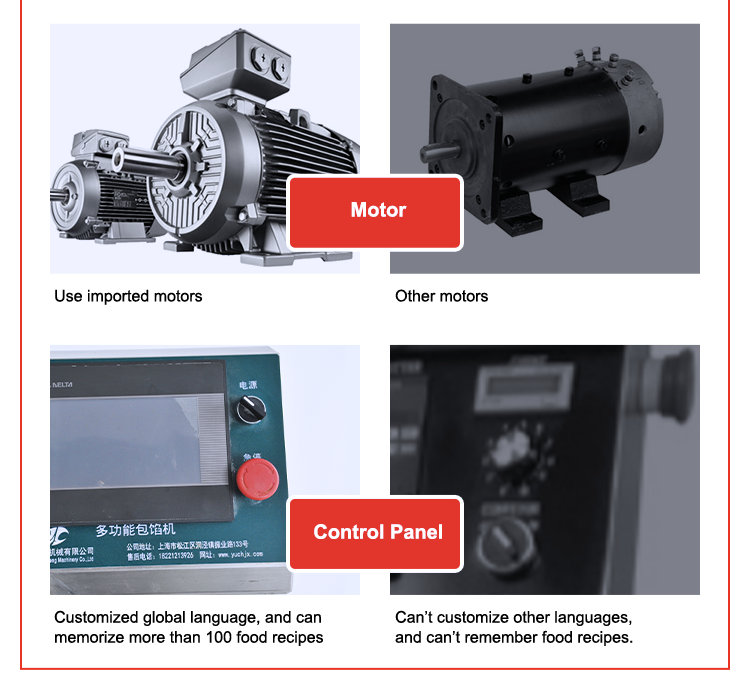

304 stainless steel material, consistent with the International food safety standards.PLC intelligent control system with a colorful touch screen, Japanese Panasonic’s frequency convertor.Big motors, two hoppers, high size machine, high capacity.

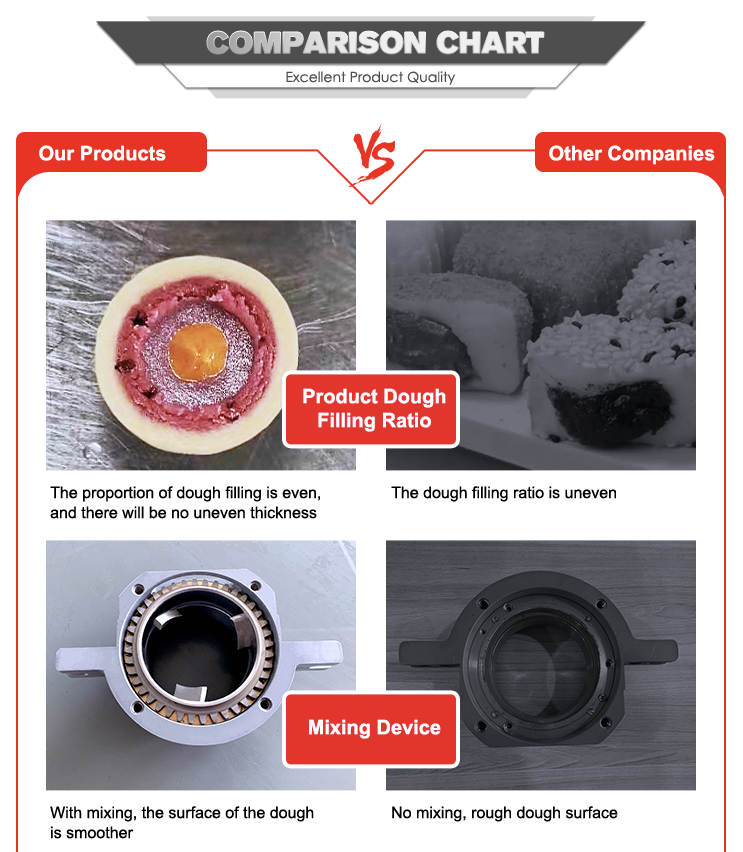

Easy and convenient, provincial people, energy saving, high degree of automation, improve production efficiency. Skin filling ratio, finished product size, production speed can meet the needs of different parts of the Kubba production.

And we have different models of large machines and small machines, the production speed and production per minute of large machines and small machines are

different, can be customized according to the needs of each customer.

Automatic Kubba Machine Description:

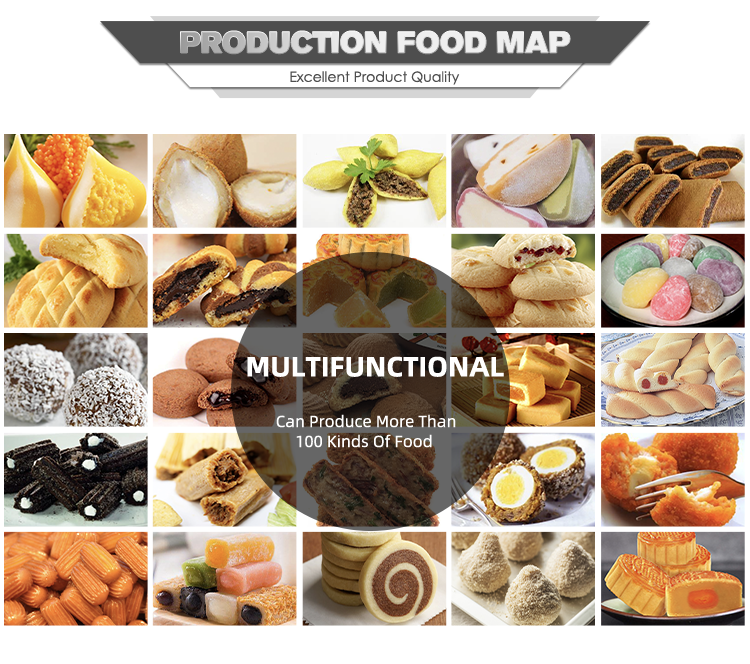

The Automatic Encrusting Machine can change different skin thickness, length, size of food by the machine.It can also change different molds for making different shaped food products.The encrusting machine can also make filling soft stuffed pastries such as kubba ( kibbeh ), coxinha, croquette, arancini, arepas, falafel, mooncake,maamoul, kahk cookie, pineapple cake, mochi, ice cream mochi, meat ball,filled cookies, double color cookies, strip cookies,ice box cookies, chocolate chip cookies, mosaic cookies, panda cookies, twist cookies, flatten filled cookies, shortbread butter cookies, designed cookies, fruit bar, fig bar, date roll, crackers, energy ball, filled date ball, sesame ball, tamarind ball, meat ball, fish ball, beef ball, and so on. And for different food, there will be different devices.

The auto encrusting machine can also make below food:

pumpkin cakes, sweetheart cakes, soft stuffed cakes, wife cakes, meat pies, tambun-biscuits, piroshki, filled churros, rice croquettes, meat pia, nastar, filled quenelle, gulab jamun, rasgulla, tulumba, bunuelos, knodel, thai moji, kebab Balls, topfenknodel, germknödel, filled Potato ball, pyzy, tamales, meat with egg, beef roll, bite size, filled pretzels, concha bread, mini stollen, apple strudel, apple pie, dinner roll, filled Bagel, polvoron, marzipan, hamburger, chicken kiev, ang guh kueh, donuts, filled hamburg, pate, knish, scotch egg, pan fried beef bun, crystal dumpling, rice dumpling, stuffed buns, kuefteta, savory beans, gratin Pie, brownie with filling, amaretto, rumkugeln, rocmia, etc.

The fillings in the encrusting and forming machine could be jam, chocolate, cream, ice cream, bean paste, minced meat, paste mixed with small nuts (sesame, corn, peanut).

The YC-168 model encrusting machine is our small encruster special designed for making Kubba, this small encruster can make other stuffed food as well.