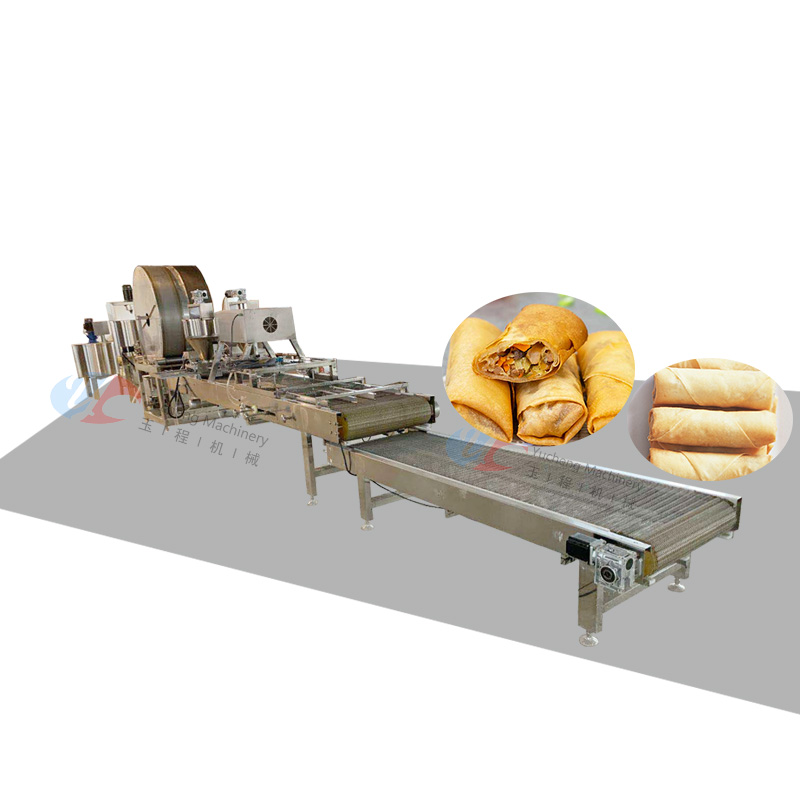

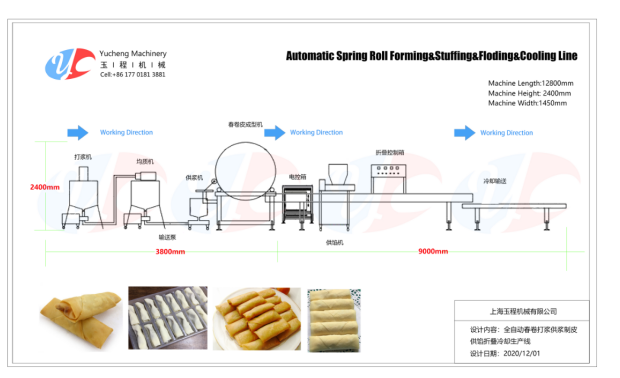

Full Automatic Spring Roll Machine Production Line

Features

*The complete equipment rack is made of SUS304 grade stainless steel

*The heating method is electromagnetic heating, which saves 30% energy than traditional heating methods

*The baking wheels, rollers, drive shafts, etc. are made of carbon steel and polyurethane

*The conveyor mesh belt is a 1.5mm herringbone mesh belt

*The inside and outside of the transfer pump are made of 304 material

*The mold is made of 6061 high-strength aluminum alloy

*All panels of the whole set of equipment have a decorative thickness of 1.2mm and a reinforcement of 5mm-8mm

Single Row Full Automatic Spring Roll Production Line

|

Item |

Dimension(mm) |

Weight(KG) |

Power(KW) |

Qty(Set) |

|

Conveyor belt of spring roll machine (transmission and packingpart) |

6000×600×1400 |

400 |

3 |

1 |

|

Spring roll machine main machine (bake wheel sizing part) |

1700×700×2400 |

800 |

60 |

1 |

|

Stuffing machine |

900×700×1500 |

120 |

0.5 |

1 |

|

200L dough paddle mixer |

650(DIA)×1300 |

80 |

1.5 |

1 |

|

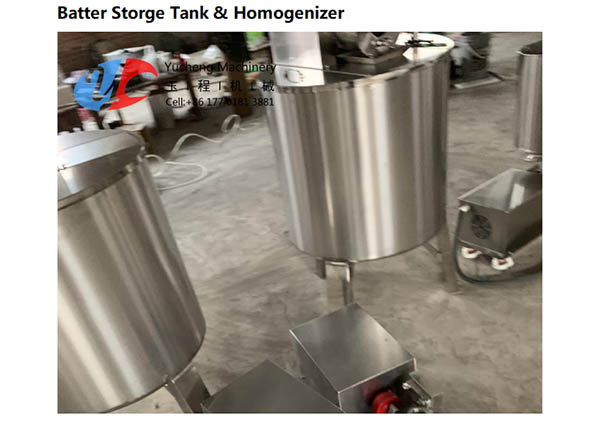

200L slurry tank (contains a special homogenizer for flour slurry) |

650(DIA)×1300 |

100 |

2.2 |

1 |

|

Surface paddle transfer pump |

800×250×350 |

70 |

/ |

2 |

|

Roasting wheel smoking hood |

1400×700×500 |

40 |

/ |

1 |

|

Cooling table |

1000×500×600 |

30 |

/ |

1 |

|

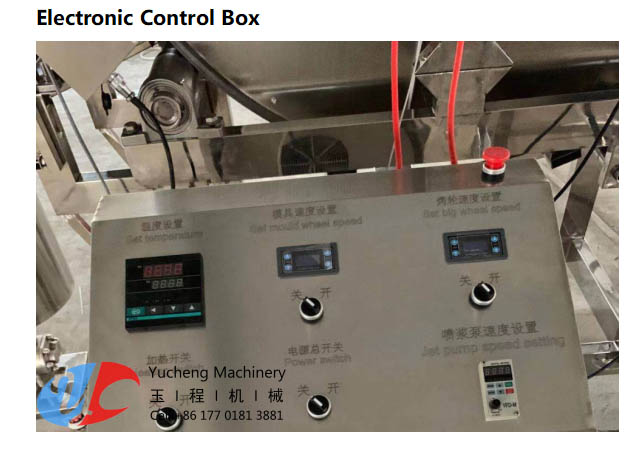

Electric control box |

600×450×1000 |

70 |

2 |

1 |

|

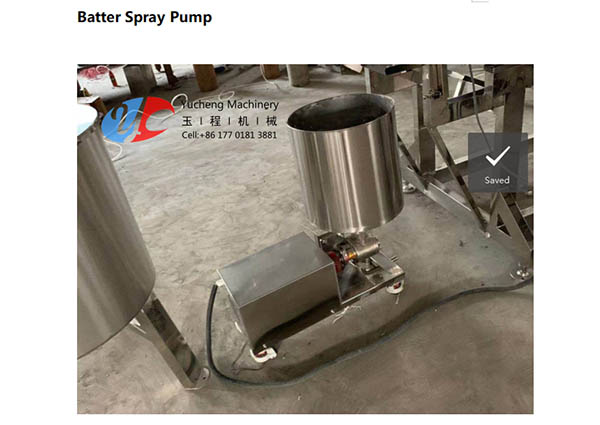

Spray pump |

650×350×1100 |

100 |

1.1 |

1 |

|

Spray mold |

400×130×130 |

10 |

/ |

2 |