professional factory for Khinkali Maker Machine - YC-168 Automatic Protein Ball Machine – Yucheng

professional factory for Khinkali Maker Machine - YC-168 Automatic Protein Ball Machine – Yucheng Detail:

YC-168 Automatic Protein Ball Machine is composed of extruder and rounder roller machine. The machine is designed independently by our engineers team. The machine have small size and we special design for small factory business or home shop use.

It is easy to making food ball without inside filling. The rounder machine can make your products more rounder than hand making. Also can add powder coater machine, coating some material like coconuts, seeds, powder, sugar, sesame, chocolate, breadcrumbs on the surface of your product.

![]()

![]()

Protein Ball Making Machine Specifications:

| Model | YC-168 |

| Capacity | 60-100 PCS/MIN |

| Product Diameter | 10-50MM |

| Power | 2.55KW |

| Voltage | 220V/50HZ |

| Weight | 380KG |

| Dimension | 2400*860*1300MM |

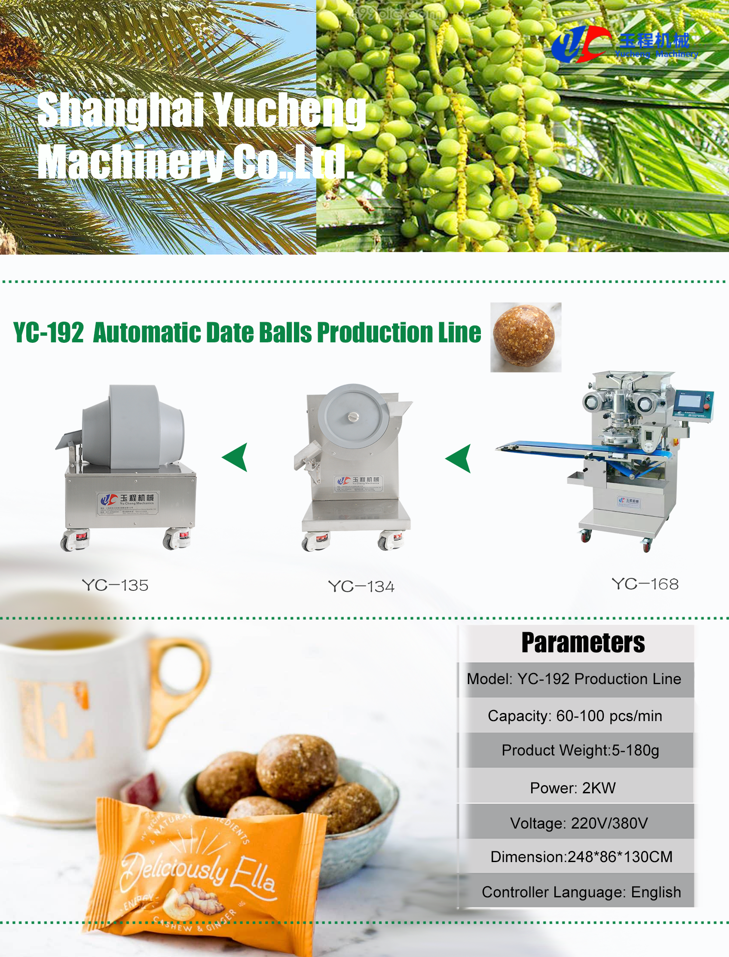

Yucheng YC-168 Model Protein Energy Ball Making Machine was originally designed to make date ball products, after years of upgrations, the protein ball making machine is now available to make many different kinds of ball products, such as date ball, protein ball, energy ball, cookie dough ball, coconut ball, bliss ball, chocolate truffle ball, tamarind ball, cake bites, dough ball, bounty ball, rum ball, Brigadeiros, sesame ball and so on. The protein ball machine is one of our most multifunctional equipment.

The energy ball making machine can make other food as well except above mentioned ball products, such as snack bar, falafel, meatball, fish ball, cheese ball, arrancini, coxinha, cookies, pies, buns, frozen food, etc.

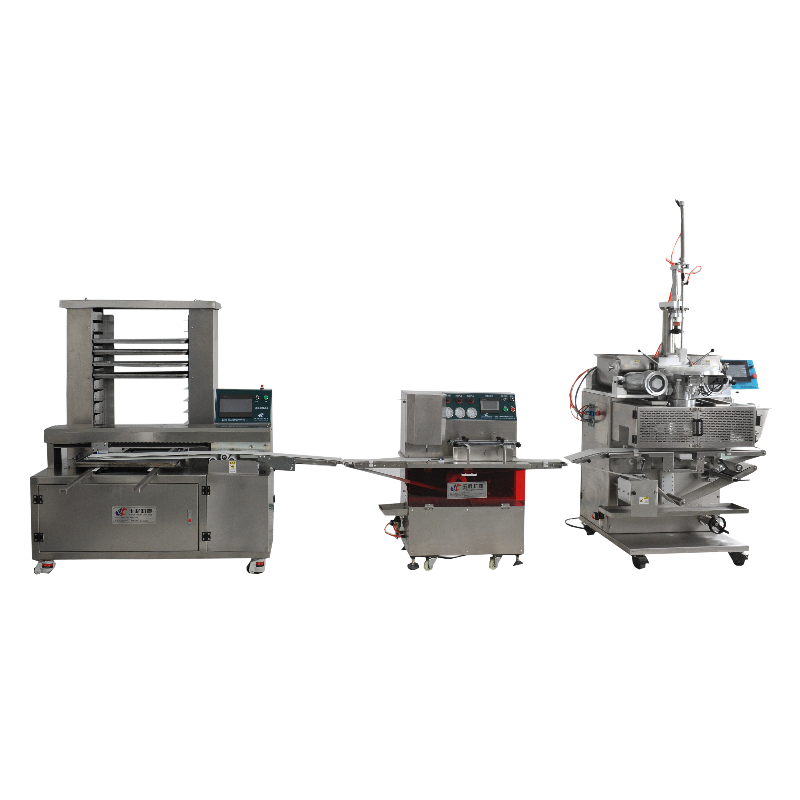

The energy ball machine consists of three machines: protein ball extruder, protein ball roller, coconut flake coating machine.

The protein ball extruder is the major machine to extrude and cut the dough or mixture, It has two hoppers on each side: left side for normal casing, right side for center filling. Each hopper has two spiral screws horizonally designed to extrude the materials to the rectifier, then down to extrusion pipe and nozzle, finally cutted by the round shutter. The protein ball extruder can form and cut each dough into uniform size and weight with weight erro +-1gram.

Besides, the protein ball maker machine copys manual working and uses PLC control system with touch screen panel, it is a fully automatic machine.

The protein ball roller machine is the secondary machine connected after the protein ball extrusion machine, the protien ball rolling machine adopts stainless steel structure and aluminum rolling wheel to roll each ball with adjustable speed and anti-sticky treatment. The ball diameter rolling range is 10mm to 50mm.

The coconut flake coating machine also adpots stainless steel structure and aluminum rotating drum, it can coat coconut flakes, smashed nuts, powder, seeds, and so on.

Besides, the protein ball extruder can coordinate with date bar cutting machine to make date cookies and fruit bars, and coordinate with maamoul stamping machine to make maamouls and mooncakes.

Protein Ball Making Machine Features:

1. Stainless steel 304,meets food hygienic standard.

2. Product diameter10-50mm,ratio and speed adjustable.maximum capacity 100pcs/min.

3. Automatic operation,rational structure, easy clean.

Why your energy ball making machine can make so many different ball products?

Our protein ball making machine is a multifunctional type model machine consisting of extrusion, rolling and coating machine. The protein ball machine hopper uses big double spiral screws horizontally to extrude the materials with strong power, also the hopper and screws are teflon coated to hold sticky materials. The protein ball rolling machine and the coconut flakes coating machine used aluminum materials structure, they are also teflon coated. That’s why our protein ball making machine can make many kinds of products even though they are different materials or formula.

What other ball products can the protein ball rolling machine make?

The protein ball rolling machine can make other ball products like rum ball, Brigadeiros, chocolate truffles, oatmeal ball, cake bites, coconut ball, sesame seed ball, mazipan ball, bounty ball, Bunuelos, cheese ball, potato ball, and so on. So the protein ball making machine is also rum ball making machine, brigadeiros making machine, chocolate truffles making machine, sesame ball making machine, etc.

Can you protein ball machine make other food?

Our protein ball machine can make other food as well. Except the protein ball roller machine and coconut flake coating machine, the major machine is the protein ball extruder, which is our YC-168 model Automatic Encrusting Machine. The protein ball extuder machine is designed to make both filling and non-filling food like cookies, maamoul, date rolls, pies, frozen food,etc. For more details, please view our YC-168 Automatic Encrusting Machine.

What size range can the protein energy ball machine make?

Normally, the protein energy ball machine can make ball diameter from 10mm to 50mm, we can customize bigger size if customer require, for example, we customized a 65mm diameter ball for our Canadian customer to make energy ball.

What is the lightest weight your energy ball machine make?

Normally our energy ball machine can make food weight range from 10g to 250g, the lightest weight we ever made is 6g.

How many moulds and rolling wheel do you supply for the energy ball making machine?

One machine has one piece of nozzle mould and rolling wheel. If customer need extra ones, we need to charge cost price.

What if I have more than one ball sizes, can your energy ball rolling machine make it?

Our energy ball rolling machine has one rolling wheel. If customer has more than one ball size and ball diameter range is above 2mm, we suggest customer to take an extra rolling wheel. Most of our customers have only one ball size, a few of them have two sizes.

For the energy ball roller, What is the material for the rolling wheel? Do you have cheaper rolling wheel if many ball sizes?

The rolling wheel for our energy ball roller machine is aluminum materials with teflon coated. It is a little expensive, but this material is more stable and strong in rolling and more environmental for food production. There is a cheaper rolling wheel made by plastic, which our company don’t manufacture.

Can your bliss ball making machine available for extruding chocolate chips or granules?

The bliss ball making machine can hold chocolate chips or granules with size within 4mm, and for bigger chocolate chips, it will easily break and melt during the extrusion. Also bigger granules will be hard to extrude. The chocolate chips and granules have no affection on our bliss ball rolling machine. Our bliss ball machine australia is sold very well because of it’s good quality.

What materials can you coconut flake machine coat?

Our coconut flake machine can coat coconut flakes, sesame seed, fruit seeds, smashed nuts, chocolate chips, grounded powders, etc.

Can your energy bites making machine make center filling or stuffed ball? If yes, what kind materials can be used for filling?

Our energy bites making machine can make center filling ball, the filling materials can be jam, peanut butter, chocolate paste, fruit paste, chocolate liquid, etc.

What is the outside casing and center filling ration for your energy bites extruder machine?

The outside casing and center filling ration is 1:9-10:0.

Can your protein bites making machine make bar shape? Do we need to add extra machinery?

The protein bites making machine can make bar shape product by adding a extra cutting machine which is separated controlled by PLC system with touch screen.

What if my material is sticky or too hard? How to judge?

The protein ball making machine is only suitable for soft and medium hard mixture, too sticky mixture will stick to shutter and conveyor belt. Then how to budge the hardness and viscosity ?

We have more than ten years experience on the protein ball machine, we have tested thousands of customer’s materials. Firstly, We can basically judge by seeing ball photos; Secondly, we can judge by watching customer’s mixture videos. It must be fresh new made mixture, normally we require customer to squeeze the mixture by hand, so we can judge the hardness and viscosity at the same time. If it’s a hard dough, it will be hard to squeeze by hand, If it’s a sticky mixture, it won’t fall out of your hand or it won’t fall out of your belt. Thirdly, we require customer to send us their main material ration list, detailed formula will be prefered. Finally, if we still can not judge, we shall require customer to send us their materials by air, we test here in our factory.

Can the protein ball extrusion machine, protein ball roller machine, coconut flake coating machine be connected to be a full automatic line?

Yes, The three machines can be connected together one by one, each machine is separated, convenient to move and control.

What other machinery is needed for the ball production?

The energy ball machine only requires electricity, no other machinery and power source is needed.

Can we just buy the energy ball roller only?

Customer can buy the energy ball roller machine only, But without the dough extruder, customer has to make each pieces of dough by hand, then take each pieces t energy ball rolling machine by hand. This way will waste customer lots of labor and time. Besides, cutting each piece of dough can’t guarantee the dough weight, customer has to weight each piece of dough one by one, it is not a cost effective solution. In a word, We suggest customer to take the energy bar extrusion machine together.

Is the coconut flake coating machine a necessary equipment? Can we add it later in future?

The coconut flake coating machine is not a necessary equipment. Customer can add it later in future. The protein ball extrusion machine and protein ball rolling machine are the necessary equipment. If customer has requirement for coating, he can achieve it by manual operation.

Do you have a bigger coating machine?

We do have a table type coating machine, it is much bigger capacity which can be used for several energy ball making machines.

Do you have protein ball packaging machine?

We have flow type protein ball packaging machine and vertical type protein ball packaging machine for customer to choose, please contact us for more details.

Can we test the energy ball machine before purchase? How do we test?

Customers are always welcome to test our protein ball machine. Normally there are two ways for customer to test our protein ball making machine: 1. Customer visits us in person or entrust a third party to visit us for testing. 2. Customer sends us their raw materials and formula, we test for customer.

Customer can choose the most convenient way they want. For some customer who are not convenient to send us the materials, we can help purchasing the materials locally.

What if the rum ball making machine can’t make my ball after testing? Can we refund?

If our rum ball making machine can’t do customer’s materials after testing, we agree a fully refund.

Can the energy ball roller machine voltage be customized, for example 380V?

The protein ball roller machine voltage can be customized for 380V or 110V. We can add transformer for customer. The protein ball forming machine can also be customized for 220V, three phase. Our protein ball maker machine standard voltage is 220V, single phase.

Do you have spare parts for this energy bites roller machine , how often to change it?

One set of spare parts will be sent together with the energy bites machine. The spare parts include the maintenance box, sealing rings, extra nozzles, etc.

The energy bites making machine has good durability in quality, there is no need to change the spare parts as long as they are not broken.

If customer requires extra spare parts for the energy bites roller in future, we can send customer directly by air within 3 days.

What is your warranty for the chocolate truffle making machine ? What if the chocolate truffle machine broken?

For the chocolate truffle making machine, Our warranty is 12 months, life time service.

We will responsible for machine maintenance without charge during the warranty period if machine issue caused on our side. After the warranty period, We still keep our service, we only charge customer cost price for damaged parts, and send customer the spare parts by air as soon as possible.

Does this chocolate ball machine need installation and training?

Our engineer is always available for installation if customer requires; As the chocolate ball machine is small size, its complete packed and sent to customer, so no installation is needed; also the chocolate ball making machine is full automatic control by PLC with touch screen, which makes it easy to operate by operating numbers on screen, We have detailed instruction and operation videos for customer training; lastly, we have service team supporting on line service.

If customer requires our installation and commissioning service,we will arrange visa applying and schedule engineer.

Do you have any certifications for the energy ball maker machine?

For the energy ball maker machine, we have CE certification.

Which countries have you sold this energy ball forming machine to?

The protein ball making machine mainly makes date ball, energy ball and protein ball. Our biggest market is USA, UK, Australia, India, Middle east. Our protein ball machine australia is sold very well for making protein ball and bliss ball. The protein ball rolling machine australia can make both protein ball and protein bar products. Our chocolate truffle making machine is sold well in europe and The South America , especially in UK and Chile. Our date ball making machine is sold well in Middle east,especially in Dubai.

What is your delivery time for the chocolate ball making machine?

We have the chocolate ball forming machine stock, we can delivery in a week for customer.

What is the packing material for the chocolate truffle maker?

The chocolate truffle maker uses strong export standard wooden box,fumigation free.

What is the transportation for this chocolate truffle equipment?

We have shipping and plane for customer to choose for the transportation. The chocolate truffle equipment is not big size, if customer in a rush, he can consider the transportation by air. We can arrange here if customer has no agent.

What is your payment term for the energy ball making machine?

Our payment term is 30% deposit as down payment, Rest 70% paid before shipment.

How to order the energy ball making machine?

After customer confirming the order, We will officially draw customer a formal proforma invoice with detailed protein ball machine information, trade terms and our bank information. Customer can choose bank transfer, credit card or other ways to arrange the 30% down payment.

After receiving customer’s down payment, we will inform customer and officially start the order to manufacture the protein ball machine.

With all that said, what is the price for the protein energy ball making machine?

As the top manufacturer and expert for the protein energy ball machine, our protein ball making machine price will be most competitive and reasonable. For knowing the energy ball making machine price, please contact us immediately for the latest promotions and prices!

Product detail pictures:

Related Product Guide:

We have now numerous great personnel members good at advertising, QC, and working with kinds of troublesome dilemma from the creation course of action for professional factory for Khinkali Maker Machine - YC-168 Automatic Protein Ball Machine – Yucheng , The product will supply to all over the world, such as: Colombia, Jordan, Thailand, To meet the requirements of specific customers for each bit more perfect service and stable quality merchandise. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.