Chocolate Mochi Cookies Encrusting Machine

Advantages of chocolate chip cookie production line:

High production efficiency: The automated production line can greatly increase the production speed of chocolate chip cookies and meet the needs of mass production.

Stable product quality: By precisely controlling the production process, we ensure that the taste, size and shape of each batch of cookies are consistent, thereby ensuring the stability of product quality.

High raw material utilization rate: The design of the production line can usually reduce the waste of raw materials and improve the use efficiency of raw materials such as chocolate beans.

Low labor costs: Automated production lines reduce reliance on labor and can significantly reduce labor costs.

Food safety is guaranteed: High-standard purification workshops and automated production lines help ensure the hygienic safety of products and reduce the possibility of human contamination.

Improved brand influence: Efficient production capabilities support companies to quickly respond to market changes, launch new products in a timely manner, and strengthen brand image building.

Strong market adaptability: able to quickly adjust product types and production volume according to market demand to maintain the company’s market competitiveness.

Innovation-driven development: Through continuous technological innovation, we improve the automation and intelligence level of the product line and promote the sustainable development of the enterprise.

he recipe for making chocolate chip cookies mainly includes the following ingredients:

Butter: usually needs to be softened at room temperature. As one of the basic ingredients of cookies, it provides a crispy texture.

Sugars: White and brown sugar not only provide sweetness but also affect the color and texture of the cookie.

Eggs: Used to bind the batter, adding stability and richness.

Flour: Low-gluten flour is the main dry ingredient for making cookies, which affects the structure of the finished product.

Cocoa powder: gives the cookies a chocolate flavor.

Baking soda: acts as a leavening agent to help cookies expand during baking to create a fluffy texture.

Vanilla extract: adds aroma and enhances flavor.

Salt: Enhances other flavors and makes sweetness more prominent.

Chocolate Beans: Heat-resistant chocolate beans provide extra chocolate flavor and texture.

In addition, when preparing the ingredients, you need to pay attention to the butter being completely liquefied and the mixture to be cooled before adding the eggs. During the preparation process, all dry ingredients should be sifted into the liquid ingredients, and then gently mixed until a uniform batter is formed. Finally, the batter is shaped and refrigerated for a while before being sliced and baked to perfection.

Our factory

Our factory is a manufacturing facility that produces goods or products. lt isequipped with machinery, equipment, and tools necessary for the pro.duction process. The factory may specialize in producing a specifictype of product or produce a range of products depending on thedemand and market needs.

The factory may employ a large number of workers who are responsi-ble for operating the machinery, monitoring the production process,and ensuring quality control. The workers may be organized into dif-ferent departments or teams based on their skills and expertise.

The factory may also have a management team responsible for over-seeing the operations, managing resources, and ensuring compliancewith safety and environmental regulations.

The production process in a factory typically involves several stages,including raw material procurement, manufacturing, quality control,.packaging, and distribution. The factory may source raw materialsfrom suppliers, manufacture the product using various processes suchas assembly lines, test the product for quality, package it for distribu-tion, and finally ship it to customers or retailers.

Factories play a crucial role in the economy by providing employmentopportunities, contributing to the growth of industries, and supplyinggoods and products to meet the demands of consumers.

FAQ about shanghai yucheng machinery co.,ltd

● What products does Shanghai Yucheng Machinery offer?

Shanghai Yucheng Machinery specializes in food processing machine, eapecially the encrusting machine, mainly in bakery food machine, frozen food machine, prepared food machine,and full automatic food production line.

● Where is Shanghai Yucheng Machinery located?

Our company is located in Shanghai, China, our factory is located in Jiangsu,China. You can find our detailed address on the Contact Us page.

● Can I request a customized machinery solution for my specific needs?

Yes, we offer customization services to meet the unique requirements of our clients,contact us to discuss your specific needs, we can customize the food production line according to your factory layout and requirements.

● Does Shanghai Yucheng Machinery provide after-sales support?

Yes, we provide comprehensive after-sales support, including technical assistance, spare parts availability, and maintenance services.

● What is the warranty period for Shanghai Yucheng Machinery products?

The warranty period for our products is one year,please refer to the product documentation or contact our customer service for warranty details.

● How can I request a quotation for a specific machine?

To request a quotation, you can fill out the online inquiry form on our website or contact our sales team via Email or Whatsapp.

● Are there any upcoming events or exhibitions where I can see Shanghai Yucheng Machinery products?

We regularly participate in industry events and exhibitions. Please check our Events page on the website for the latest updates on our participation.

● Can I find Shanghai Yucheng Machinery on social media platforms?

Yes, you can follow us on facebook, youtube, instagram for the latest updates, product announcements, and industry news.

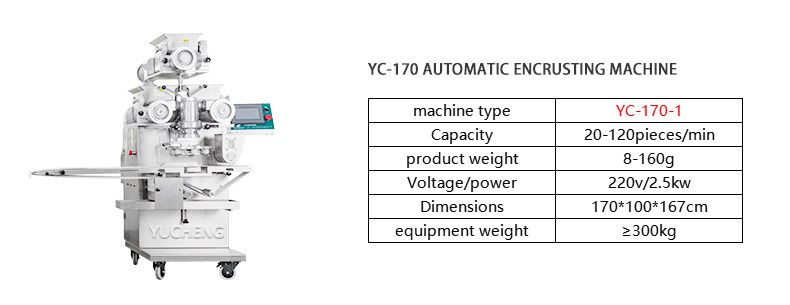

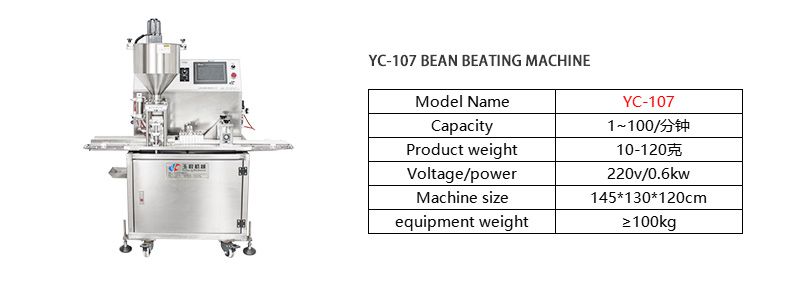

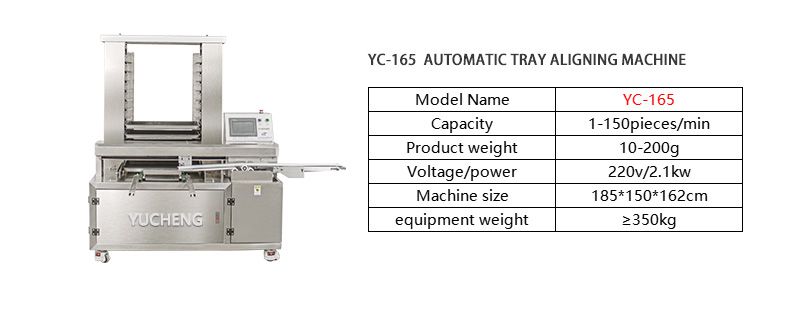

FAQ about YC-170 cookies production line

Q: What is a full automatic cookies production line?

A: A full automatic cookies production line is a series of interconnected machinery and equipment designed to automate the entire process of producing cookies. It includes various stages such as ingredient mixing, dough preparation, shaping, baking, cooling, and packaging. The production line is designed to minimize manual labor, increase production efficiency, and maintain consistent quality and output.

Q: What are the advantages of a full automatic cookies production line?

A: Some advantages of a full automatic cookies production line include:

.Increased Efficiency: Automation reduces manual labor and increases production speed and capacity.

.Consistent Quality: The automated process ensures uniformity and consistency in product size, shape, and quality.

.Cost Savings: Reduced labor costs and increased production efficiency result in cost savings over time.

.Enhanced Food Safety: Full automatic production lines often incorporate food-grade materials, ensuring hygiene and safety standards are met.

.Versatility: The production line can be adjusted to produce various types of cookies and other baked goods.

.Time Savings: Automated processes save time, allowing for higher production volumes and faster delivery.

Q: What types of cookies can be produced on a full automatic cookies production line?

A: A full automatic cookies production line can produce a wide range of cookies, including but not limited to classic cookies like chocolate chip, oatmeal, peanut butter, sugar cookies, as well as specialty cookies like sandwich cookies, filled cookies, and shaped cookies. The production line can be configured to handle different dough consistencies and shapes to accommodate various cookie types.

Q: What materials are used in the construction of the production line?

A: Full automatic cookies production lines are typically constructed using food-grade materials such as stainless steel (SUS) to ensure hygiene and durability. Stainless steel is resistant to corrosion, easy to clean, and complies with international food safety standards.

Q: What spare parts are used in the production line?

A: High-standard spare parts from reputable brands like DELTA, Mitsubishi, Siemens, etc., are commonly used in full automatic cookies production lines. These spare parts are known for their reliability, durability, and compatibility with the machinery, ensuring stable and efficient operation of the production line.

Q: Is customization possible for the production line layout?

A: Yes, customization of the production line layout is possible to fit the specific requirements and available space in the customer’s factory. Shanghai Yucheng Machinery can work with customers to design a layout that optimizes workflow, space utilization, and production efficiency.

Q: What is the production capacity of a full automatic cookies production line?

A: The production capacity of a full automatic cookies production line can vary depending on the specific model and configuration. However, Shanghai Yucheng Machinery offers a high-speed capacity of 1000 pcs/min, which indicates the line’s ability to produce up to 1000 cookies per minute.

Q: How can I ensure the quality and safety of the produced cookies?

A: Quality and safety can be ensured by implementing proper quality control measures throughout the production process. This can include regular testing of ingredients, monitoring production parameters, conducting quality checks at various stages, and following food safety guidelines and regulations. Additionally, maintaining and cleaning the machinery regularly will help ensure hygienic production conditions.