Full Automatic Cookies Production Line

Full Automatic Cookies Production Line

High Speed: Shanghai Yucheng Machinery offers a high-speed, fully automatic cookies production line with a capacity of 1000 pcs/min.

Customized: Our cookies production line layout can be customized according to the customer’s factory size and requirements.

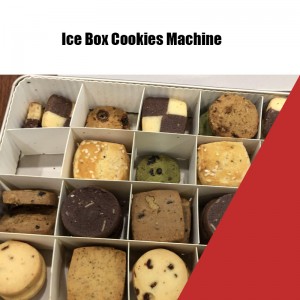

Multifunctional :Cookies production line is multifunctional and capable of producing a variety of products such as cookies, biscuits, mochi ice cream, arancini, and more.

SUS Material:Our cookies production line is constructed using SUS (stainless steel) material, ensuring it meets international food-grade standards for hygiene and safety.

High Standard: Our cookies production line use high-standard parts from reputable brands like DELTA, Mitsubishi, Siemens, etc., ensures durability and stable operation of the production line.

Machine layout for the full automatic cookies production line :

*Raw Material Storage Area

*Mixing and Dough Preparation

*Shaping and Forming

*Baking

*Cooling and Packaging

Full Automatic Cookies Line Videos:

About Us

Shanghai Yucheng Machinery Co., Ltd. is a manufacturer specialized in food machinery for over 13 years with well-equipped testing facilities and strong technical force.We have multifunctional Encrusting Machines and production lines which can produce full automatic cookies machine system line, full automatic puff pastry machine system line, full automatic bread machine system line,full automatic spring roll machine system line,fig roll newton cookies machine,soft cookies machine, chocolate cookies machine,soft cookies machine, biscuit machine, mochi ice cream machine,pastry machine,Bread machine, protein ball machine,mooncake machine, maamoul machine, dimsum machine, spring roll machine, steamed bun machine,siopao machine, siomai machine, dumpling machine and many other kinds of food.

Our Team

Spare Parts Manufacturing

Spare Parts Warehouse

Machine Testing and Stock

Machine Packing and Shipping

Our Achievements

FAQ

Q: What is a full automatic cookies production line?

A: A full automatic cookies production line is a series of interconnected machinery and equipment designed to automate the entire process of producing cookies. It includes various stages such as ingredient mixing, dough preparation, shaping, baking, cooling, and packaging. The production line is designed to minimize manual labor, increase production efficiency, and maintain consistent quality and output.

Q: What are the advantages of a full automatic cookies production line?

A: Some advantages of a full automatic cookies production line include:

- Increased Efficiency: Automation reduces manual labor and increases production speed and capacity.

- Consistent Quality: The automated process ensures uniformity and consistency in product size, shape, and quality.

- Cost Savings: Reduced labor costs and increased production efficiency result in cost savings over time.

- Enhanced Food Safety: Full automatic production lines often incorporate food-grade materials, ensuring hygiene and safety standards are met.

- Versatility: The production line can be adjusted to produce various types of cookies and other baked goods.

- Time Savings: Automated processes save time, allowing for higher production volumes and faster delivery.

Q: What types of cookies can be produced on a full automatic cookies production line?

A: A full automatic cookies production line can produce a wide range of cookies, including but not limited to classic cookies like chocolate chip, oatmeal, peanut butter, sugar cookies, as well as specialty cookies like sandwich cookies, filled cookies, and shaped cookies. The production line can be configured to handle different dough consistencies and shapes to accommodate various cookie types.

Q: What materials are used in the construction of the production line?

A: Full automatic cookies production lines are typically constructed using food-grade materials such as stainless steel (SUS) to ensure hygiene and durability. Stainless steel is resistant to corrosion, easy to clean, and complies with international food safety standards.

Q: What spare parts are used in the production line?

A: High-standard spare parts from reputable brands like DELTA, Mitsubishi, Siemens, etc., are commonly used in full automatic cookies production lines. These spare parts are known for their reliability, durability, and compatibility with the machinery, ensuring stable and efficient operation of the production line.

Q: Is customization possible for the production line layout?

A: Yes, customization of the production line layout is possible to fit the specific requirements and available space in the customer’s factory. Shanghai Yucheng Machinery can work with customers to design a layout that optimizes workflow, space utilization, and production efficiency.

Q: What is the production capacity of a full automatic cookies production line?

A: The production capacity of a full automatic cookies production line can vary depending on the specific model and configuration. However, Shanghai Yucheng Machinery offers a high-speed capacity of 1000 pcs/min, which indicates the line’s ability to produce up to 1000 cookies per minute.

Q: How can I ensure the quality and safety of the produced cookies?

A: Quality and safety can be ensured by implementing proper quality control measures throughout the production process. This can include regular testing of ingredients, monitoring production parameters, conducting quality checks at various stages, and following food safety guidelines and regulations. Additionally, maintaining and cleaning the machinery regularly will help ensure hygienic production conditions.