YC-400 Automatic Encrusting Machine

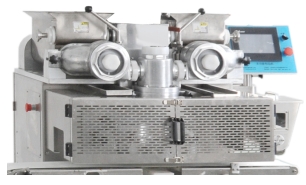

YC-400 Automatic Encrusting Machine alos called YC-400 Encruster or YC-400 Extruding Machine , it is the food processing equipment primarily used for making various filled foods. The working principle of YC-400 Automatic Encrusting Machine involves a series of mechanical movements that fill the dough and filling together in a certain proportion. Subsequently, through actions like cutting, it produces complete food items. The usage scenarios for YC-400 Automatic Encrusting Machine are widespread, encompassing various food processing plants, restaurants, hotels, and other establishments. In these settings, YC-400 Automatic Encrusting Machine can enhance production efficiency and product quality, making them essential equipment in modern food processing.

Technicial Parameters

|

YC-400 Automatic Encrusting Machine |

|

Capacity:10-100pcs/min |

|

Product Weight: 10-1500g |

|

Power: 4KW |

|

Electricity: 220V,50/60Hz,1Phase |

|

Dimension: 1810*1000*1380mm |

|

Weight:450KG |

Structure of YC-400 Automatic Encrusting Machine

1.Hopper:

YC-400 Automatic Encrusting Machine has two hoppers, one for dough and one for filling.

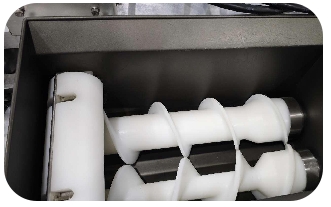

2.Rectifier:

Through paddles, it evenly divides the raw materials into equal portions.

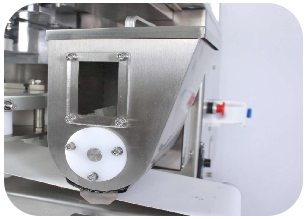

3.Mold tube:

Fills the filling into the middle of the dough.

4.Cutter:

Cuts the filled dough column into products of equal size and weight.

5.Conveyor belt:

Places the formed food onto the conveyor belt.

6.Flour sprinkler:

Sprinkles flour onto the conveyor belt to prevent food from sticking to it.

7.Waste box:

Scrapes excess raw materials stuck on the belt into the waste box.

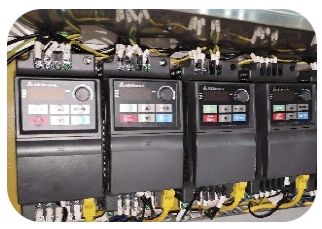

8.Electrical box:

The machine's motor, inverter, and PLC are all housed in the box at the back of the machine.

Food Production Range

Food Length

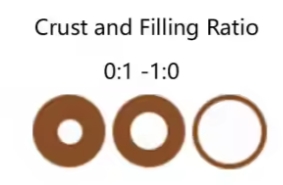

Crust and Filling Ratio

Food Weight Range

YC-400 Automatic Encrusting Machine Spare Pare List

|

|

Item |

Brand |

|

1 |

Approach Switch |

XUNG (Shanghai) |

|

2 |

Touch Screen |

DELTA (Taiwan) |

|

3 |

PLC |

|

|

4 |

Frequency Invertor |

|

|

5 |

Power Switch |

|

|

6 |

Serve Motor |

|

|

7 |

Serve Motor Driver |

|

|

8 |

Synchronous Belt |

Mitsuboshi(Japan) |

|

9 |

Reduction Motor |

Nissei(Japan) |

|

10 |

Planet Gear Speed Reducer |

VIGE (Dongguan) |

|

11 |

Intermediate Relay + Base |

CHINT |

|

12 |

A.C. Contactor |

|

|

13 |

Breaker |

|

|

14 |

Cutter Motor |

OTG |

|

15 |

Intermix Motor |

|

|

16 |

Third Filling Motor |

|

|

17 |

Conveyor Motor |

ZOYOY |

|

18 |

Dusting Motor |

|

|

19 |

Speed Adjuster |

|

|

20 |

Conveyor Belt (PU , 3260×130mm) |

YONGLI (Taiwan) |

|

21 |

Bearings |

HRB(Harbin), |

|

22 |

Voltage |

220V,50HZ,Single Phase |

FAQs for YC-400 Automatic Encrusting Machine

1.What types of filled foods can the YC-400 Automatic Encrusting Machine produce?

The YC-400 is versatile and can be used to make various filled foods, including pastries, dumplings, and other stuffed products.

2.What is the working principle of the YC-400 Automatic Encrusting Machine?

The machine operates based on a series of mechanical movements that combine dough and filling in precise proportions. Subsequent actions, such as cutting, result in the production of complete food items.

3.In what settings can the YC-400 Automatic Encrusting Machine be used?

The machine is suitable for a wide range of settings, including food processing plants, restaurants, hotels, and other establishments involved in food production.

4.What are the key components of the YC-400 Automatic Encrusting Machine?

The machine consists of several components, including hoppers for dough and filling, a rectifier for even distribution of raw materials, a mold tube for filling placement, a cutter for shaping, a conveyor belt for transportation, a flour sprinkler, a waste box, and an electrical box housing the motor, inverter, and PLC.

5.What are the advantages of the YC-400 Automatic Encrusting Machine?

The machine offers several advantages, including a high level of automation, stable product quality, the ability to produce various food items, ease of operation and maintenance, and customizable programming for different languages and product formulas.

6.Can the YC-400 Automatic Encrusting Machine handle products with multiple fillings or colors?

Yes, the machine has the option to install four hoppers, allowing the production of products with three fillings or colors.

7.Are there optional choices or accessories available for the YC-400 Automatic Encrusting Machine?

Yes, optional choices include SUS304 spare parts, cutter safety cover, and hopper safety cover.

8.How is the cleaning process facilitated for the YC-400 Automatic Encrusting Machine?

The machine is designed with features such as an enlarged mold tube, reducing cleaning time by 80%. Additionally, the inner filling tube adopts Japan Rheon technology, ensuring smooth extrusion of the original material and facilitating easy cleaning.

9.Is the YC-400 Automatic Encrusting Machine suitable for products with a high oil content?

Yes, the machine's hopper is equipped with a sealing device to prevent leakage, making it suitable for food products with a large oil content.

10.What is the unique feature of the mixing structure in the YC-400 Automatic Encrusting Machine?

The mixing structure allows for the adjustment of the smoothness and toughness of the outer dough, enabling the production of rotating products such as two-color cookies, twist cookies, and spiral cookies.

11.How does the YC-400 Automatic Encrusting Machine ensure the protection of raw materials and filling during the production process?

The machine employs a counter-pushing method for the screw, with a smaller front-end pitch, reducing damage to the filling. The end bearing is designed to be sturdy, minimizing the risk of damage.

12.What is the role of the rectifier in the YC-400 Automatic Encrusting Machine, and how does it contribute to the smooth material flow?

The rectifier, through paddles, rotates 90 degrees for material pushing, which is an improvement over other machines that rotate 180 degrees. This design protects raw materials, ensuring smoother material flow.

13.Can the YC-400 Automatic Encrusting Machine accommodate different product formulas, and how many can it memorize?

The machine is capable of memorizing up to 99 different product formulas, allowing for flexibility in production. The programming language is customizable, supporting languages such as English, Russian, Arabic, Spanish, Portuguese, and more.

14.What technology is used for the paddles and screw connection of the rectifier, and what is its significance?

Electrolysis technology is used, providing a beautiful finish to the paddles and screw connection of the rectifier. This technology is currently exclusive to the YC-400 and Japanese Rheon machines.

15.How does the YC-400 Automatic Encrusting Machine address the cleaning process, and what percentage of cleaning time can be saved?

The machine's design, with an enlarged mold tube and efficient inner filling tube technology, saves approximately 80% of cleaning time, contributing to easier maintenance.

16.What safety features are available as optional choices for the YC-400 Automatic Encrusting Machine?

Optional safety features include SUS304 spare parts, a cutter safety cover, and a hopper safety cover, ensuring the safety of operators during the machine's operation.

17.Can the YC-400 Automatic Encrusting Machine be used for innovative product designs, such as two-color cookies and twist cookies?

Yes, the machine's unique mixing structure is a highlight, allowing for the production of rotating products like two-color cookies, twist cookies, and spiral cookies, providing versatility in product designs.

18.What future expansions or capabilities are possible with the YC-400 Automatic Encrusting Machine?

The machine is designed to allow for the installation of four hoppers, enabling the production of products with three fillings or three colors, providing additional flexibility for diverse product offerings.

19.What language options are available for the programming of the YC-400 Automatic Encrusting Machine?

The programming language is customizable, and the machine supports various languages, including English, Russian, Arabic, Spanish, Portuguese, and more.

20.How does the YC-400 Automatic Encrusting Machine contribute to the protection of food products with a high oil content?

The hopper is equipped with a sealing device, preventing the leakage of oil and ensuring that food products with a high oil content remain intact during the production process.

Post time: Jan-10-2024