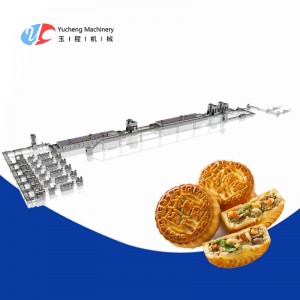

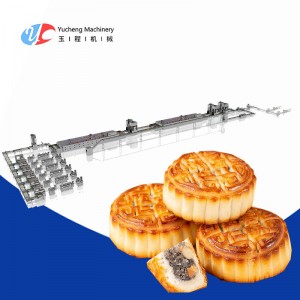

Full Automatic Maamoul Machine System

Full Automatic Maamoul Machine System

Full Automatic Maamoul Machine System Includes:

Automated Mixer: An automatic mixer combines the ingredients for the maamoul dough, ensuring consistent blending and texture. It accurately measures and dispenses ingredients like flour, water, butter, sugar, and other additives.

Kneading System: The dough is kneaded by automated equipment to achieve the desired consistency. This step helps develop gluten and create a smooth, elastic dough.

Dough Shaping and Filling:

Dough Extruder: An automatic dough extruder shapes the dough into uniform sheets or cylinders. It can be adjusted to create different maamoul sizes and shapes.

Filling Dispenser: For filled maamoul, an automated system dispenses the desired filling (nuts, dates, etc.) onto the dough. The quantity of filling is precisely controlled for consistency.

Forming and Pressing:

Stamping System: An automated mold system presses the dough and filling together to create the final maamoul shape. The molds are designed to produce different designs and sizes.

Baking:

Tunnel Oven: The formed maamoul are placed on a conveyor belt and pass through an automated oven for baking. The oven’s temperature and baking time are controlled to achieve even baking and desired texture.

Cooling and Sorting:

Cooling Conveyor: After baking, the maamoul are moved onto a cooling conveyor, where they cool down to room temperature before further processing.

Packaging:

Automatic Packaging Machine: The cooled maamoul are automatically packaged into various packaging options, such as boxes, pouches, or trays. The packaging machine can weigh, fill, seal, and label the packages.

Quality Control:

Integrated Control System: The entire production line is managed by an integrated control system. This system monitors equipment performance, process parameters, and data related to production efficiency and quality.

Remote Management:

Remote Access: Many modern automatic maamoul lines allow managers to remotely monitor and control the production process. This can be done through computer interfaces or even mobile applications.

Maintenance and Cleaning: