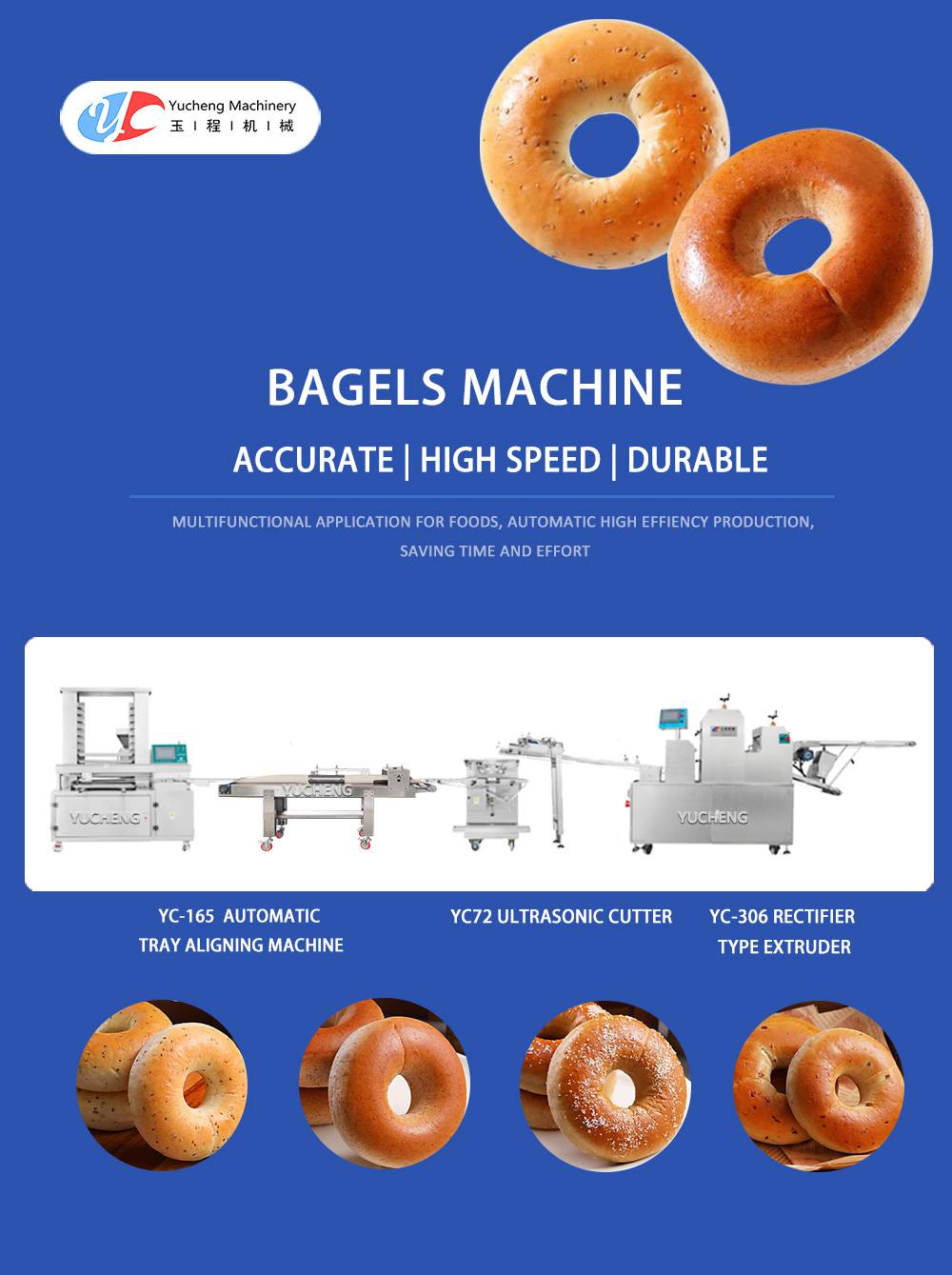

Automatic Bagels Bread Machine Bagels Production Line Bagels Equipment Bagels Maker

Automatic Bagels Bread Machine Bagels Production Line Bagels Equipment Bagels Maker

MACHINE FEATURES

1.Accurate: YC-868 Bagels machine will dividing bagels dough into uniform size and thickness, to make the accurate weight of bagels .

2.High Speed: YC-868 bagels machine capacity can reaches 40 pcs/min, saves lot of time.

3.Adjustable Size: You can order different bagels forming machine to get various size of bagels.

4.Easy Operation: YC-868 bagels machine allows you to customize the entire process according to your preferences. You can set specific times for dough rollling, production speed, and size.

5.Large Capacity: YC-868 bagels machine have large capacity to accommodate the quantity of bagel dough you want to produce , fully automated bagels production line can be customized according to your factory size and machine layout.

6.Multifunctional: YC-868 bagels machine can produce bagels, bread, baguette, toast, stuffed buns, puff pastry,etc.

PARAMETERS

1.YC-868 Horizontal Encrusting Machine

Capacity:10-100pcs/min

Product Weight: 10-1000g

Power: 2KW

Electricity: 220V,50/60Hz,1Phase

Dimension: 3500*920*1750mm

Weight:600KG

2.YC-330 Automatic Dough Roller

Capacity:10-15KG/One Time

Dough Thickness:8-20mm

Power: 4KW

Electricity: 380V 50Hz, 3 Phase

Dimension: 1100*900*1200mm

Weight: 600KG

3.YC-302 Automatic Dough Divider

Belt Width:200mm

Power: 0.5KW

Electricity: 220V 50/60Hz,1phase

Dimension: 2430*640*1460mm

Weight: 220KG

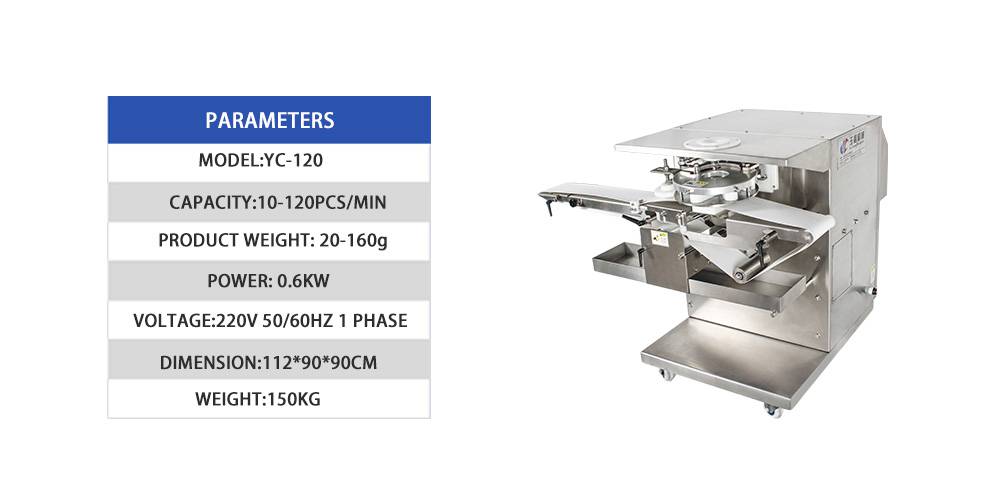

4.YC-120 Stuffed Bun Cutter

Capacity:10-90pcs/min

Product Weight: 10-100g

Power: 0.6KW

Electricity: 220V 50/60Hz,1phase

Dimension: 1670*900*1300mm

Weight: 200KG

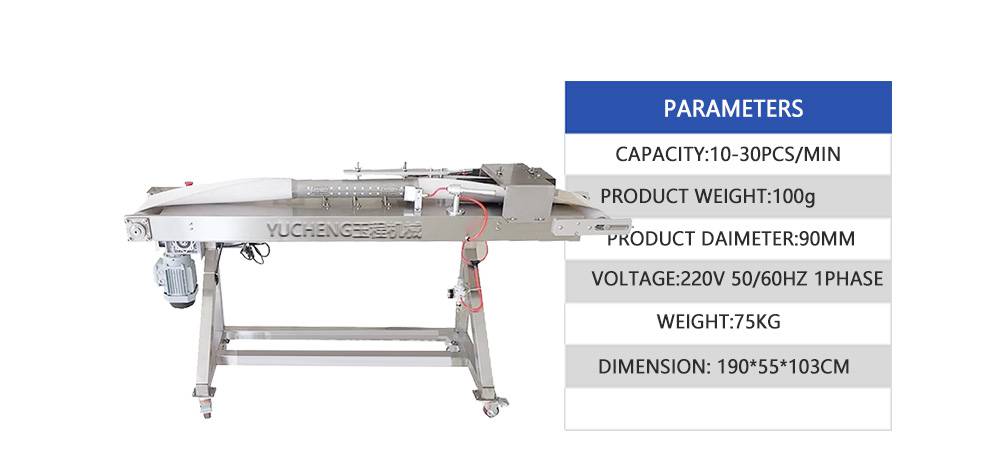

5.YC-405 Bagel Forming Machine

Capacity:10-30pcs/min

Product Weight: 80-150g

Power: 0.5KW

Electricity: 220V 50/60Hz,1phase

Dimension: 1900*550*1030mm

Weight: 150KG

6.YC-165Automatic Tray Aligning Machine

Capacity:10-100pcs/min

Product Weight: 15-1000g

Power: 2.1KW

Electricity: 220V 50/60Hz

Dimension: 1680*1650*1620mm

Weight: 400KG

MACHINE VIDEOS

Bagels machine working flow

The working flow of a bagel machine involves several stages, from dough preparation to the final baked product.

|

YC-330 |

Automatic Dough Roller |

|

YC-302 |

Automatic Dough Divider |

|

YC-868 |

Automatic Horizontal Rolling Encrusting Machine |

|

YC-402 |

Automatic Bun Cutter |

|

YC-405 |

Bagel Forming Machine |

|

YC-165 |

Automatic Tray Aligning Machine |

1.Dough Mixing:The process begins with the mixing of bagel dough ingredients. High-gluten flour, water, yeast, sugar, and salt are commonly used.

2.Dough Rolling: Put the mixed dough into dough roller, then it will be rolled automatically.

3.Dividing :The bagels dough is divided into uniform sheets by YC-302 Automatic Dough Divider and YC-868 Automatic Horizontal Rolling Encrusting Machine , so the bagels weight and size will keeps same.

4.Shaping:The divided dough portions are shaped by YC-405 Bagel Forming Machine into the classic ring shape bagels.

5.Aligning: After bagels were formed, then it will be transferred into baking tray automatically by YC-165 Automatic Tray Aligning Machine.

6.Fermentation:After aligning the bagels into baking trays, pu the baking trays into the proofer, the fermentation period allows the yeast to leaven the dough, resulting in the development of flavor and texture.

7.Boiling:Bagels are traditionally boiled before baking,put the bagels into hot water boiled about 1 minutes, then slightly drain the waters on bagels surface, this step contributes to the characteristic chewiness of bagels.

8.Baking:After boiling, the bagels are transferred to the baking stage, put the bagels into baking ovens to get a golden-brown crust, baking time is around 15 minutes.

9.Cooling:Once baked, bagels are moved to a cooling area, cooling down the bagels temperature before packaging.

10. Topping Application (Optional):Some bagel machines include mechanisms for applying toppings such as sesame seeds, poppy seeds, onions, or other desired toppings. This step is optional and depends on the type of bagel being produced.

11.Quality Control and Inspection:After bagels cooling down, quality control person will check the bagels to ensure that each bagel meets specific standards, Inspection may include checking for size, color, and overall quality.

12.Packaging:The final step is packaging the bagels with automated packaging systems.

It is the whole process of bagels production flow,these processes contributes to the reliable and standardized production of bagels, and ensuring that each bagel meets quality standards.

About Us

Shanghai Yucheng Machinery Co., Ltd. is a manufacturer specialized in food machinery for over 13 years with well-equipped testing facilities and strong technical force.We have multifunctional Encrusting Machines and production lines which can produce full automatic cookies machine system line, full automatic puff pastry machine system line, full automatic bread machine system line,full automatic spring roll machine system line,fig roll newton cookies machine,soft cookies machine, chocolate cookies machine,soft cookies machine, biscuit machine, mochi ice cream machine,pastry machine,Bread machine, protein ball machine,mooncake machine, maamoul machine, dimsum machine, spring roll machine, steamed bun machine,siopao machine, siomai machine, dumpling machine and many other kinds of food.

Our Team

Spare Parts Manufacturing

Spare Parts Warehouse

Machine Testing and Stock

Machine Packing and Shipping

Our Achievements

*国家高新技术企业 NATIONAL HIGH-TECH ENTERPRISE

*中国食品工业协会会员 CHINA NATIONAL FOOD INDUSTRY ASSOCIATION MEMBERS

*2023上海市高新技术成果转化项目 2023 SHANGHAI HIGH-TECH ACHIEVEMENT TRANSFORMATION PROJECT

*2021中国烘焙十佳品牌制造商 2021 CHINA’S TOP TEN BAKERY BRAND MANUFACTURERS

*2021年度中国烘焙行业发展杰出贡献奖 2021 OUTSTANDING CONTRIBUTION AWARD FOR THE DEVELOPMENT OF CHINA’S BAKING INDUSTRY

*中华全国工商业联合会-烘焙业工会理事 CHINA FEDERATION OF INDUSTRY & COMMERCE-BAKING INDUSTRY UNION DIRECTOR

*江西省工商联合会-面包商会副会长单位 JIANGXI PROVINCIAL FEDERATION OF INDUSTRY AND COMMERCE- BREAD CHAMBER OF COMMERCE VICE PRESIDENT

*江西省工商联合会-面包商会战略协作单位 JIANGXI PROVINCIAL FEDERATION OF INDUSTRY AND COMMERCE-STRATEGIC COOPERATION UNIT OF BAKERY CHAMBER OF COMMERCE

*2020中国烘焙行业发展峰会“行业之力”2020 CHINA BAKERY INDUSTRY DEVELOPMENT SUMMIT “INDUSTRY POWER”

*2021中式糕点博览会最佳参展商 BEST EXHIBITOR OF 2021 CHINESE PASTRY EXPO

BAGELS STYLE

A bagel (Yiddish: בײגל, romanized: beygl; Polish: bajgiel; also spelled beigel)[1] is a bread roll originating in the Jewish communities of Poland.[2] Bagels are traditionally made from yeasted wheat dough that is shaped by hand into a torus or ring, briefly boiled in water, and then baked. The result is a dense, chewy, doughy interior with a browned and sometimes crisp exterior.

Bagels come in various flavors and styles, each with its unique characteristics. Here is a list of different kinds of bagels:

1.Plain Bagel:The classic and most traditional type, typically made with a simple dough of high-gluten flour, water, yeast, sugar, and salt.

2.Everything Bagel:Coated with a mix of sesame seeds, poppy seeds, dried garlic, dried onion, and salt, giving it a rich and savory flavor.

3.Poppy Seed Bagel:Topped with poppy seeds for a distinctive appearance and a slightly nutty flavor.

4.Sesame Seed Bagel:Coated with sesame seeds, providing a nutty taste and a subtle crunch.

5.Onion Bagel:Infused with dried onions or onion powder for a savory and aromatic flavor.

6.Garlic Bagel:Featuring the addition of garlic, either in minced or powdered form, for a robust and savory taste.

7.Salt Bagel:Sprinkled with coarse salt on the surface, offering a slightly salty flavor and enhancing the overall taste.

8.Cinnamon Raisin Bagel:Sweetened with cinnamon and studded with raisins or currants, creating a delightful blend of sweetness and spice.

9.Blueberry Bagel:Made with blueberries or blueberry flavoring, imparting a fruity and sweet taste.

10.Chocolate Chip Bagel:Incorporating chocolate chips into the dough for a sweet and indulgent variation.

11.Pumpernickel Bagel:Made with a mix of whole wheat and rye flours, molasses, and cocoa powder, resulting in a dark color and a distinct flavor.

12.Whole Wheat Bagel:Using whole wheat flour instead of or in addition to white flour, providing a heartier and nuttier taste.

13.Egg Bagel:Enriched with eggs in the dough, giving the bagel a softer texture and a slightly richer flavor.

14.Jalapeño Bagel:Infused with diced jalapeños or jalapeño flavoring for a spicy kick.

Sun-Dried Tomato Bagel:Featuring sun-dried tomatoes in the dough for a tangy and savory taste.

15.Asiago Bagel:Sprinkled with Asiago cheese on top, adding a savory and nutty flavor.

16.Spinach and Feta Bagel:Incorporating chopped spinach and crumbled feta cheese for a flavorful and savory option.

17.Cranberry Bagel:Studded with dried cranberries for a sweet and tart taste.

18.Honey Wheat Bagel:Sweetened with honey and made with a combination of whole wheat and white flours for a wholesome flavor.

19.Rye Bagel:Made with a portion of rye flour, offering a distinctive flavor reminiscent of traditional rye bread.

MACHINE APPLICATION

Bagel machines are primarily used in the food manufacturing and baking industry, especially in settings where there is a demand for large-scale production of bagels.

1.Commercial Bakeries:Large-scale commercial bakeries use bagel machines to produce a high volume of bagels efficiently.

2.Bagel Shops and Specialty Bakeries:Bagel shops and bakeries that specialize in producing a variety of bagel flavors and styles often invest in bagel machines to ensure consistency and meet customer demand.

3.Food Manufacturing Facilities:Industrial-scale food manufacturing facilities, especially those producing frozen or packaged bagels for retail distribution, use bagel machines to achieve high production capacity and efficiency.

4.Wholesale Distribution:Companies engaged in wholesale distribution of bagels to grocery stores, cafes, and other retail outlets utilize bagel machines to meet the demand for large quantities of bagels.

5.Cafeterias and Food Service Providers:Institutions such as schools, hospitals, and catering services that require a steady supply of bagels for their food service operations may employ bagel machines to meet their production needs.

6.Chain Restaurants and Fast-Food Outlets:Chain restaurants and fast-food outlets that include bagels on their menus may use bagel machines to ensure uniformity and efficiency in the production of bagels for their establishments.

7.Frozen Food Manufacturers:Bagel machines are commonly used in the production of frozen bagels for the retail market. These machines contribute to the automation and standardization of the manufacturing process.

8.Research and Development Labs:Facilities engaged in the research and development of new bagel recipes or variations may use bagel machines to test and scale up their production processes.

9.Large-scale Retail Bakeries:Retail bakeries operating on a larger scale, especially those with a focus on diverse bread products, may incorporate bagel machines to expand their product offerings.

10.Industrial Kitchens in Institutions:Large institutions such as universities, prisons, and corporate cafeterias with in-house food production may use bagel machines to meet the demand for freshly baked bagels.

FAQs

(Frequently Asked Questions) about YC-868 Bagel Machines:

1.What is a bagel machine?

YC-868 bagel machine is an industrial equipment of making bagels, from dough mixing to the bagels forming and aligning to baking trays.

2.How does a bagel machine work?

YC-868 bagel machines including dough mixing, fermentation, dividing, shaping, boiling, baking, cooling, and optional topping application.

3.What types of bagels can be produced with a bagel machine?

Bagel machines can produce a variety of bagel types, including plain, seeded (sesame, poppy, etc.), flavored, and specialty bagels.

4.Can a bagel machine handle different dough recipes?

YC-868 bagel machines can handle various bagel dough recipes, allowing for customization in terms of ingredients and flavors.

5.What is the production capacity of a bagel machine?

YC-868 bagel machines production capacity depends on bagels size, generally speed is 40pcs/min.

6.Is a bagel machine suitable for small-scale bakeries?

YC-868 bagel machines are designed for bakery factory and bakery shop.

7.Can a bagel machine produce different sizes of bagels?

Yes, YC-868 bagel machine is adjustable to produce different sizes of bagels, need to change YC-405 bagels forming machine, each set YC-405 can only produce one size bagels.

8.Are bagel machines easy to operate?

YC-868 bagel machine are designed with user-friendly interfaces. Training may be required initially, but once operators are familiar with the machine, it is generally straightforward to use.

9.What safety features are included in bagel machines?

YC-868 bagel machine safety features include emergency stop buttons, safety interlocks, and protective guards.

10.Can bagel machines be customized for specific requirements?

YC-868 bagel machine offer customization options to accommodate specific production requirements.

11.What is the warranty period for a bagel machine?

YC-868 bagel machine warranty time is one year.

12. What products does Shanghai Yucheng Machinery offer?

Shanghai Yucheng Machinery specializes in food processing machine, eapecially the encrusting machine, mainly in bakery food machine, frozen food machine, prepared food machine,and full automatic food production line.

13. Where is Shanghai Yucheng Machinery located?

Our company is located in Shanghai, China, our factory is located in Jiangsu,China. You can find our detailed address on the Contact Us page.

14. Can I request a customized machinery solution for my specific needs?

Yes, we offer customization services to meet the unique requirements of our clients,contact us to discuss your specific needs, we can customize the food production line according to your factory layout and requirements.

15. Does Shanghai Yucheng Machinery provide after-sales support?

Yes, we provide comprehensive after-sales support, including technical assistance, spare parts availability, and maintenance services.

16. What is the warranty period for Shanghai Yucheng Machinery products?

The warranty period for our products is one year,please refer to the product documentation or contact our customer service for warranty details.

17. How can I request a quotation for a specific machine?

To request a quotation, you can fill out the online inquiry form on our website or contact our sales team via Email or Whatsapp.

18. Are there any upcoming events or exhibitions where I can see Shanghai Yucheng Machinery products?

We regularly participate in industry events and exhibitions. Please check our Events page on the website for the latest updates on our participation.

19. Can I find Shanghai Yucheng Machinery on social media platforms?

Yes, you can follow us on facebook, youtube, instagram for the latest updates, product announcements, and industry news.